The battle against stubborn toilet clogs always rages on! But ya don’t need to worry. I'm about to give ya some tried-and-true techniques to unclog your commode and restore peace to your bathroom kingdom. So roll up your sleeves, and let's dive right in!

Most Popular

CLOGS CAUSE

WORRIES.

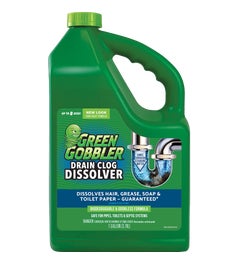

GREEN

GOBBLER

CLEARS BOTH.

- Categories: Drain Clog Removers

With a little ingenuity and some everyday household items (and somethin' else ya can get on this website), ya can unclog your toilet without a plunger. Whether ya opt for a household science experiment or call in the heavy artillery with Green Gobbler, that toilet clog should be a thing of the past.

- Categories: Drain Clog Removers

When traditional methods fail, let me, the Green Gobbler, become your new partner in crime. A persistent clog can make you miserable, but I can save the day with my Drain Clog Dissolver. This powerful stuff is designed to tackle tough clogs fast, effectively, and best of all, safely.